Electroless nickel plating: the process and its benefits

Electroless nickel plating offers a great solution for those looking to improve the durability and uniformity of a surface, as well as increasing aspects such as conductibility, ductility, and lubricity.

What is electroless nickel plating?

A type of alloy treatment, the electroless nickel plating method sees the substrate being cleaned to remove surface contaminants, and to ensure that the substrate is perfectly smooth and free of corrosion. For this reason, grit blasting may be a part of the cleaning phase. Next, grease and oils are removed by applying chemical compounds that also work to balance the pH levels and stabilise the process as a whole.

The plating process itself is achieved through an autocatalytic technique, in which the substrate is placed in a bath of hypophosphite and nickel salt. The amount of phosphorus present in this solution will dictate how hard or corrosion-resistant the nickel plating will ultimately be. Adjusting the solution also affords customisation of other qualities of the coating, such as shininess of finish.

The best way to determine if electroless nickel plating is the right technique for your application is to consult a specialist in the field such as www.poeton.co.uk/standard-treatments/electroless-nickel-plating/.

The benefits of this approach

There can be some appealing benefits to using the electroless plating technique, such as an ability to coat the substrate with greater levels of precision, thereby affording greater levels of customisation. It is also a simpler process, as unlike other methods, it does not require an electrical charge or catalyst. Discover more about the advantages of this technique here:

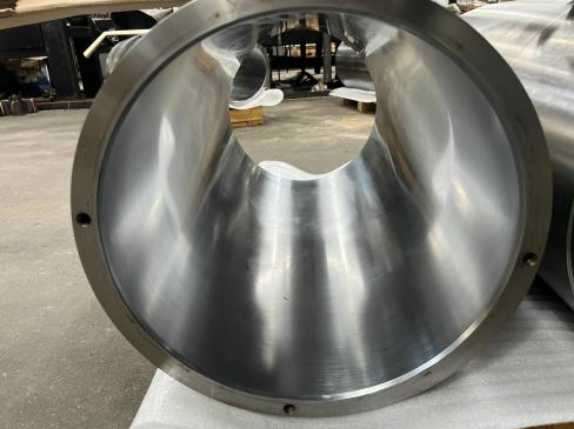

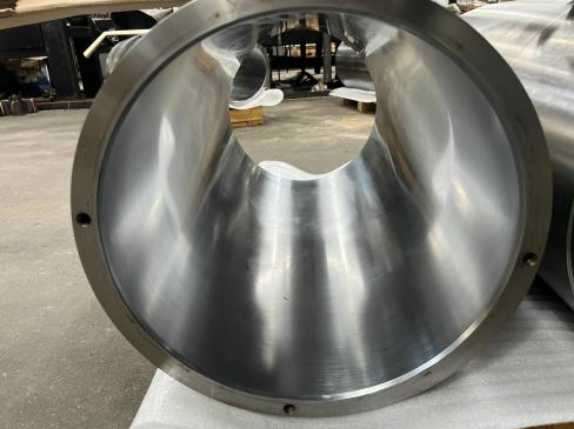

The result of electroless nickel plating is a substrate that is better able to withstand friction and other wear and tear, as well as featuring a more even, consistent surface finish, regardless of the shape or complexity of the item. The plated substrate will also benefit from increased hardness and better resistance to corrosion thanks to the reduced porosity. This makes electroless nickel plating a popular choice for coating a range of metals, such as stainless steel, aluminium, titanium, brass, and copper.